Update after the first experiences: August 2010

We were on holidays on the Adriatic for six weeks and the logbook says we produced 3000 liter / 800 US gal. of freshwater during that time. The average flowrate on the permeate side was 0.8 to 1.0 liter per minute (48 to 60 liters or 12 to 16 US gall. fresh water per hour) with the Karcher pump regulated down to approx. half the performance with an additional electronic control device (costs about 20 EUR / 25 USD). So, this is a result that one may expect realistically. This electronic control turned out to be very useful: It allows a "soft start" of the pump, which reliefs the DC-AC inverter, one may control the Amp draw, and at - presumably - two thirds of full-performance of the pump the noise is reduced considerably to about one third of full-performance.

On the life-span of the Kaercher Pump we still have to work. The watermaker had been shut-down from May until July. During that time the whole installation was filled with the recommended pickling fluid. When we put it into operation again in July, the pump leaked after several hours. I had a spare pump on board and exchanged it (a task of 5 minutes). The rest of the time the watermaker worked flawlessly.

I changed the operating style: Before that I would start the watermaker, produce water, and then simply shut it down, intending to use it the following day again. After the pump exchange I modified the way of operation: After each use I flushed the system with fresh water (product water), so that the pump would be filled with fresh water. This, I estimated, should help, as the household pressure washer should be designed to be filled with fresh water continuously.

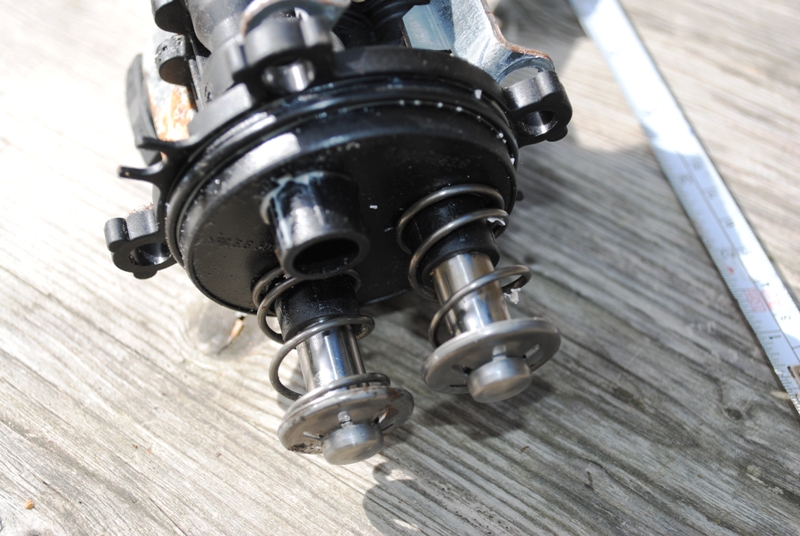

When back home I disassembled the leaking pump to understand what had happened. One of the steel plungers (i.e. a small piston) was corroded and had got stuck in the plastic cylinder. Although the plungers are made of SS, the grade is obviously not that high. Moreover, one has to take into consideration, that the recommended cleaning/preservation dissolution is a weak acid (Sulfuric Acid). Thus, it is also likely that this caused corrosion.

At the moment, I am not yet sure whether it was the lack of flushing after use, the acidic disinfectant, or both - or neither, that caused the malfunction. I am working on it and shall report.

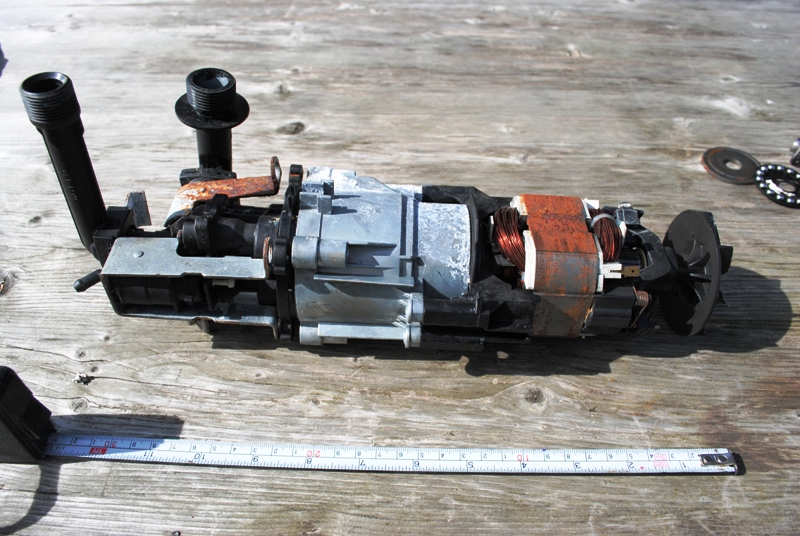

Here are some photos from the Karcher's interior: