Modifications in 2011

We were happy with the Kärcher-solution. Without thinking much I simply bought a new Karcher, just to make sure that it would work throughout the whole summer, and it did. The “new” way of operating it (flushing after each use with about 5 l / 1 ½ gal. of fresh water, thus making sure that fresh water is inside of the Karcher most of the time). So, the concept turned out to work perfectly for our needs. During 2011 again more than 3,000 l / 800 gal. fresh water were produced. I made the installation “looking nicer” with a more appropriate panel. And I optimized the electrical installation, which turned out to be a task of its own. What had happened?

Just to recall:

Just to recall:

- The Karcher (1.4 kW) draws roughly 110 Amps at full load.

- The alternator delivers 110 Amps nominally (i.e. at full rpm and when “cold”, which means at about 20°C / 68°F).

There are no “nominal conditions” on board. The engine is usually running at 1600 rpm (cruising) instead of 3000 rpm (WOT), the temperature in the engine compartment is rather 60°C / 140°F. The alternator heats up to about 100°C / 212°F when under full load conditions.

Under these conditions two things happen:

Under these conditions two things happen:

- The output of the alternator goes down gradually when temperature goes up.

- When the alternator gets close to 100°C / 212°F the Sterling “power charger”, which boosts the batteries, switches to normal mode. The effective output of the alternator then is rather some 40 Amps instead of 110 Amps.

So, after a while the batteries go down although there are more than 300 Amp hours aboard of Dido. This is so because of the so called “Peukert-factor” (Pf). The Pf means: If a battery is rated e.g. 100 Amp hours it delivers 1 Amp per hour for 100 hours. So, if you light a bulb that draws 1 Amp it will run for 100 hours. If you draw 2 Amps, it will run for 50 hours etc.

Now, this linear calculation changes when you start to draw more than some 20 Amps and / or when the surrounding temperature becomes higher than 20°C / 60°F. If you draw e.g. 50 Amps, the same battery is empty after 20 minutes rather than after ½ hour. The faster you draw the Amps the less you get out of the battery. This is what the Pf tells us.

In Dido’s case this meant: After one hour of running the watermaker the batteries were 2/3 empty. At the same time the alternator was extremely hot, delivering only some 40 Amps. Topping the batteries would take at least 2 hours of motoring at cruising speed.

So, I was back to a sophisticated question from the very beginning: Where to get the energy from?

What I did:

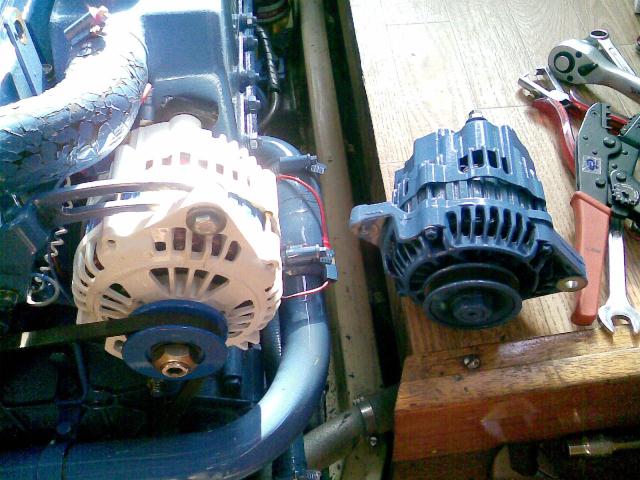

First I changed the pulleys of the engine. The pulley of the alternator was already the smallest possible, following Nigel CALDER’s recommendations in “Boatowner’s Mechanical and Electrical Manual” (3rd 2005, McGraw-Hill). So, I had to increase the engine’s main pulley. In order to maintain the waterpump’s rpms I also hat to increase the waterpump pulley.

Bigger pulleys on the crankshaft mean more rpm on the alternator at lower engine rpm. More rpm on the alternator mean more Amps. Easy, isn’t it? But when you make the crankshaft pulley bigger, not only the alternator goes faster, but also the waterpump. It is driven by the same pulley and belt. In order to keep the ratio (important for the waterpump bearing and the circulation speed of the cooling water) the waterpump pulley must also be changed to a bigger one.

I measured. I measured again. I measured a third time. Then I went to a colleague who would machine new pulleys. With the new pulleys the alternator should deliver 80 Amps at the engine’s idle speed. And at some 1200 rpm it should deliver 100 per cent, or 110 Amps. Only when getting close to the engines max. rpm (3000) – which practically never happens – the alternator would come close to its rated maximum rpm.

Those were some hard days while waiting for the new pulleys! I was so curious how they would work – and I was so confident that they would seriously contribute to a better performance.

A few days later I got the new pulleys back.

I mounted them, found a matching V-belt, and – found out that they were too big! The V-belt now touched the housing of the raw water pump!

Of course, the whole thing happened a few days before our annual spring trip, so there was simply no time to have new pulleys machined. So, I installed a ball bearing with a screw onto the pump housing, which should deflect the belt a little bit. Of course, this would increase belt wear. But spare belts would solve this problem.

There was also little time for test running the new installation. However, everything was running, and the alternator was charging. So why bother?